Abstract: Anyang Forging Press Group’s branch company-- Anyang Lianda CNC Precision Forging Co,. Ltd are mass producing near net shape forging bevel gear thread on CNC fully hydraulic die forging hammer, the implementation of the project on anti-fatigue driving axle spiral bevel gear manufacturing technology industrialization is significant.

Anyang Lianda CNC Precision Forging Co,. Ltd was founded in 2011, which is a subsidiary of Anyang Forging (Group) Machinery Industry Co., Ltd. With engaged in precision forgings production and combination with production, learning and research, our company has developed to be an integrated modern enterprise with a whole set of process capability including drawing, R&D design, forging, machining, QC and so on; Anyang Lianda company has advanced precision forging equipment, CNC hydraulic hammer, several production lines including 31.5KJ CNC hammer, 80KJ CNC hammer, 125KJ CNC program-controlled hydraulic die forging hammer, ring rolling machine and other auxiliary equipment, heat treatment and machining equipments. Anyang Lianda company can produce high precision die forging parts maximum diameter up to 400mm or maximum weight up to 50kg.

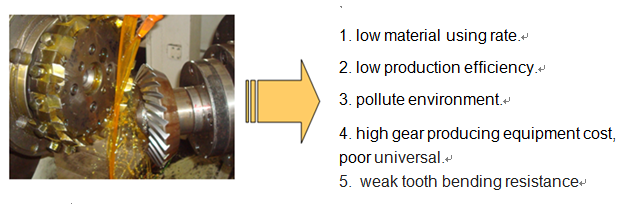

1.The usual forging spiral bevel gear way in China is as following:

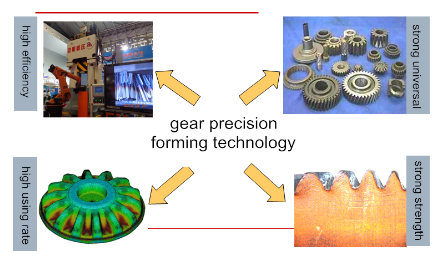

2. HIigh precision forging screw bevel gear technology process features and advantages:

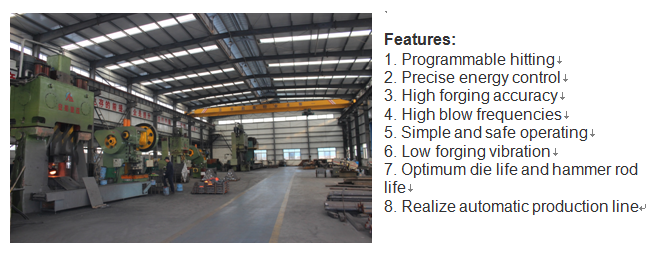

All the production equipment that producing high precision forging crown gear line in Anyang Lianda are using CNC hydraulic die forging hammer which are designed and manufactured by Anyang Forging Press Group.

Techniques advantages:

1.The precision forged gear teeth ensures complete metal flow lines, the strength is improved, after proven, the life expectancy is increased by over 70%.

2. The precision forged gear can save 15% -20% raw material, besides, saving 15-20% heat costs while heating and forging isothermal normalizing.

3. After precision forging, the teeth surface allowance is extremely minimum, the cutting residual stress is almost negligible compared with the traditional process. Subsequent thermal deformation is small, the yield is increased by 5%.

4.After precision forging, the efficiency for gear teeth machined on the dedicated machine is very high, the cost is low.

Anyang Forging Press (Group) Machinery Industry Co., Ltd. was founded in 1956, which is the biggest manufacturer of forging hammer in the world, it drafted China National manufacturing standard of forging hammer, which can offer design, research and development, manufacture, production. Anyang Forging Press Group can provide complete set forging machines including closed die forging equipments(CNC fully hydraulic die forging hammer, electro hydraulic die forging hammer, full hydraulic die forging hammer, round steel bar shearing machine , grinding steel ball skew rolling mill etc), free forging machine(pneumatic forging hammer, single frame free forging hammer, double frame open die forging hammer, bridge type open die forging hammer, hydraulic free forging press, ring rolling machine etc) and forging auxiliary machien(forging manipulator, forging charger , key driver machine etc) , also Anyang Forging Press (Group) Machinery Industry Co., Ltd. can offer worldwide customers forging solutions, choosing forging machines advice, forging technic design, forging machines etc services. Till now, Anyang Forging Press Company already exported its forging machines to USA, UK, Germany, France, Japan, Russia etc 66 countries.

Anyang Forging Press (Group) Machinery Industry Co., Ltd.

Service hotline: 0086-372-3389658

Email: info@chinesehammers.com

Website: www.chinesehammers.com